Yo! 3D printing enthusiasts and curious cats! It’s your favorite blind guy with a knack for describing things he can’t see. Today, we’re diving into the wild world of 3D printing technologies. Buckle up, because we’re about to take a roller coaster ride through the land of melted plastic, laser beams, and gooey resins!

Before we jump in, let me clarify: I’m an FDM guy through and through. That’s my bread and butter, my peanut butter and jelly, my… well, you get the idea. But don’t worry, I’ve had the pleasure of experiencing the other technologies too. It’s like being a pizza expert who’s also tried sushi – I know my stuff, but FDM is where my heart (and my printer) lies.

The Contenders in Our Printing Arena

Before we start our showdown, let’s meet our contestants:

- FDM (Fused Deposition Modeling) – The “Hot Glue Gun on Steroids”

- SLA (Stereolithography) – The “Laser Light Show in a Vat”

- SLS (Selective Laser Sintering) – The “Sandy Beach Barbecue”

- Resin Printing – The “Sticky Situation”

Now, let’s dive into each of these and see what makes them tick (or in my case, what makes them go bump in the night).

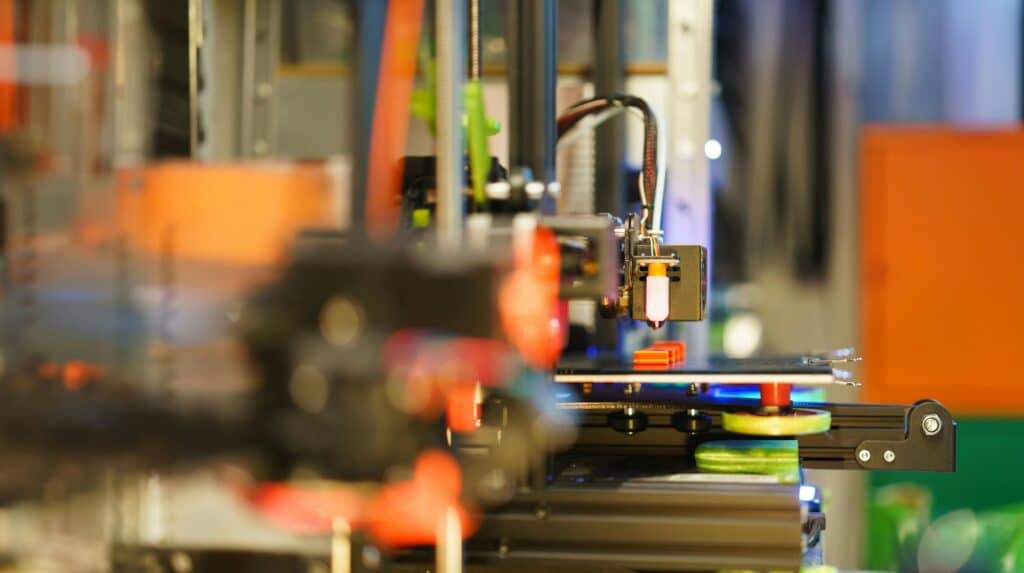

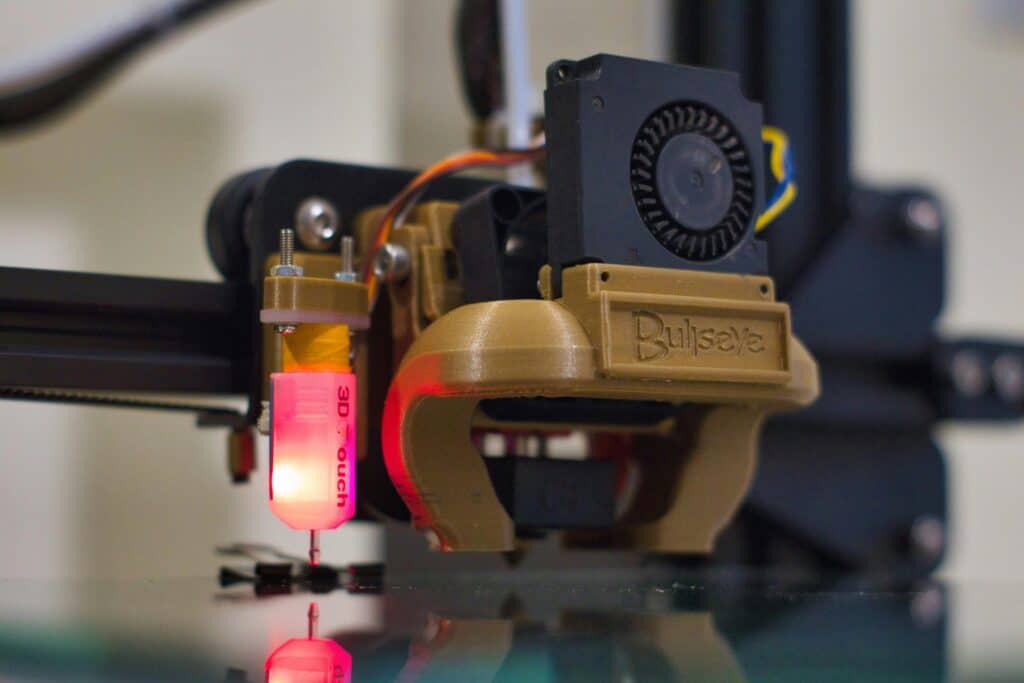

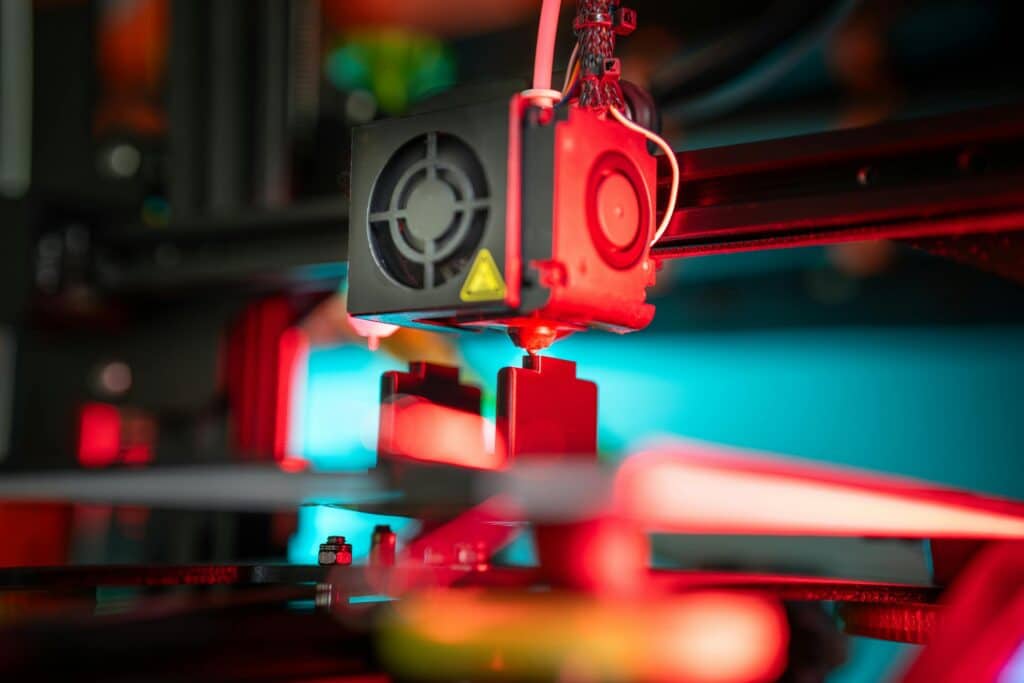

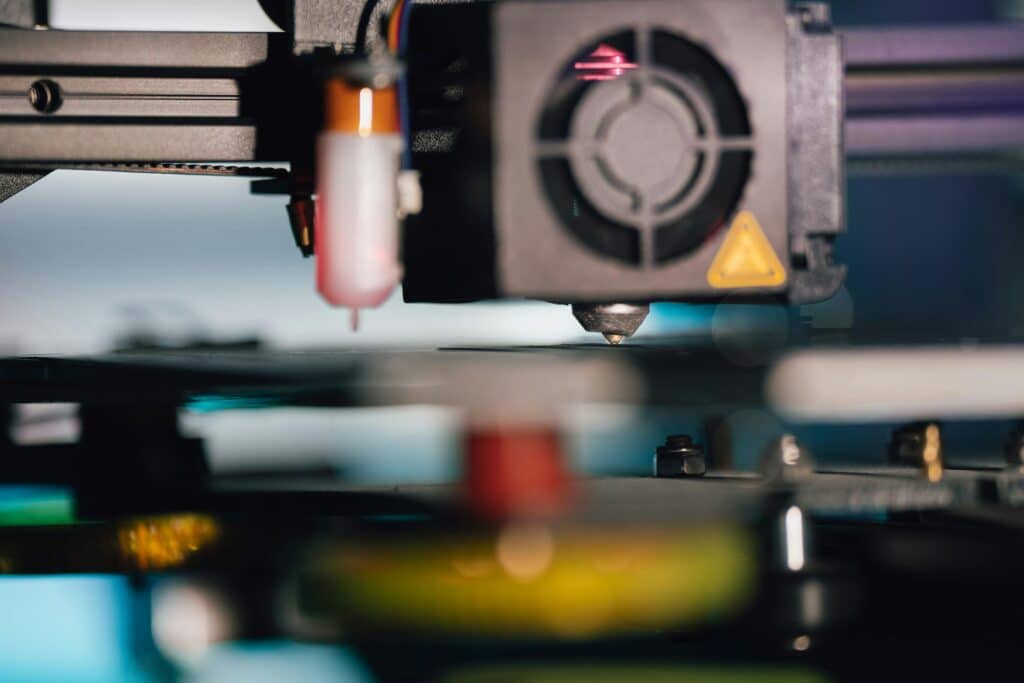

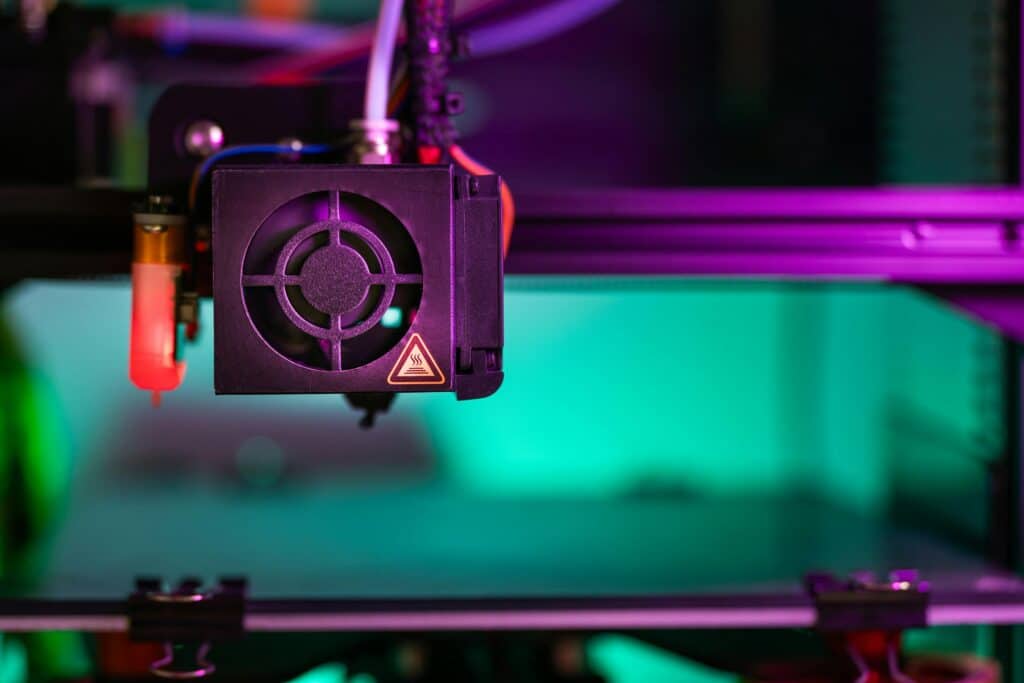

FDM: The Hot Glue Gun on Steroids

What’s the Deal?

Imagine a really smart hot glue gun attached to a robot arm. That’s basically what FDM printing is. It takes a spool of plastic filament, heats it up until it’s gooey, and then squirts it out layer by layer to build your object. It’s like drawing with melted cheese, but less tasty and more useful.

The Good Stuff

- Cheap and Cheerful: FDM printers are the budget-friendly option in the 3D printing world. Perfect for when you want to print a life-size statue of your cat but don’t want to break the bank.

- Material Variety: You can print with all sorts of plastics. Want a flexible rubber ducky? Done. A rigid action figure? No problem. A minty fresh toothbrush holder? Weird, but okay!

- Big Prints: FDM printers can go big. We’re talking “print your own furniture” big. Just don’t tell IKEA.

- Surprisingly Detailed: While FDM is often thought of as the “rough and ready” option, with the right settings and a bit of tweaking, you can achieve some impressively detailed prints. We’re talking “count the scales on your dragon miniature” level of detail.

The Not-So-Good Stuff

- Layer Lines: Your prints might look like they have a bad case of corduroy. Smooth surfaces? More like “I can feel every layer” surfaces. But hey, some people pay extra for that textured look!

- Speed: Even though FDM printers can be very fast, it’s not exactly The Flash of 3D printing. If you start printing a vase for your grandmother’s birthday, her great-grandkids might be the ones to receive it.

- Overhangs: Gravity is not your friend here. Printing overhangs can be like trying to build a house of cards in a wind tunnel.

SLA: The Laser Light Show in a Vat

What’s the Deal?

Picture this: a pool of liquid resin that hardens when you shine a light on it. Now, add a super precise laser that draws each layer of your object, hardening it bit by bit. It’s like a very slow, very precise rave for molecules.

The Good Stuff

- Smooth Operator: SLA prints are smoother than a jazz saxophone solo. No more of that corduroy look!

- Detail Deity: Want to print a scale model of a fly’s eyeball? SLA’s got your back. The detail is so fine, you might need a microscope to appreciate it fully.

- Strong and Pretty: SLA prints are not only good-looking but also surprisingly strong. It’s like that classmate who was both the valedictorian and the star athlete.

The Not-So-Good Stuff

- Sticky Situation: Post-processing is messier than a toddler’s art project. You’ll be dealing with liquid resin, which is about as cooperative as a cat at bath time.

- Size Matters: SLA printers are usually smaller than their FDM cousins. No printing life-size replicas of yourself here, unless you’re a Smurf.

- Sunlight Shy: SLA prints can be sensitive to UV light. Leave them in the sun, and they might start to look like they’ve had a bad spray tan.

SLS: The Sandy Beach Barbecue

What’s the Deal?

Imagine you’re at a beach, and you have a magnifying glass. Now, instead of frying ants (which is mean, don’t do that), you’re using the focused sunlight to fuse grains of sand into shapes. That’s basically SLS, except replace the sand with powder plastic and the magnifying glass with a high-powered laser.

The Good Stuff

- No Support Needed: SLS is like the overachiever who doesn’t need help. The unsintered powder supports the print as it’s being made. It’s printing in a sandbox!

- Complex Geometries: Want to print a scale model of your brain? SLS can handle all those wrinkles and folds without breaking a sweat.

- Strong Like Bull: SLS prints are tough cookies. They’re often used for functional parts that need to withstand some abuse.

The Not-So-Good Stuff

- Powdery Finish: Your prints might come out looking like they’ve been rolled in flour. Great for printing ghosts, not so great for everything else.

- Expensive Hobby: SLS printers cost more than my dad’s car. And his second car. Combined. (Remember, I don’t drive – I just print!)

- Not for Home Use: Unless you live in a factory or have a very understanding spouse, SLS printers are probably not making it into your living room anytime soon.

Resin Printing: The Sticky Situation

What’s the Deal?

Resin printing is like SLA’s cousin who decided to skip the laser and go straight for the UV light. It uses a vat of liquid resin and cures entire layers at once using a UV screen. It’s like if a tanning bed and a printer had a baby.

The Good Stuff

- Speed Demon: Resin printing can be faster than SLA because it cures entire layers at once. It’s the Usain Bolt of the 3D printing world.

- Detail Darling: Like SLA, resin printing can produce incredibly detailed models. Want to print a perfectly scaled chess set? Go for it!

- Smooth Criminal: The surface finish on resin prints is smoother than a buttered slide. No more layer lines to ruin your perfect miniatures.

The Not-So-Good Stuff

- Messy Business: Remember that sticky kid in elementary school? That’s you now. Liquid resin gets everywhere, and it’s about as easy to clean as glitter.

- Smelly Situation: Resin has a… unique aroma. It’s not quite “new car smell,” more like “chemistry experiment gone wrong.”

- Post-Processing Party: After printing, you’re not done. You need to wash and cure your prints. It’s like babysitting a very high-maintenance, very small child.

The Final Showdown: Which One Reigns Supreme?

Now that we’ve met our contestants, who wins? Well, like asking a parent to choose their favorite child, it’s not that simple (though we all know they have one).

FDM: My Personal Champion

FDM is like the reliable family sedan of 3D printing. It might not be the flashiest, but it gets the job done without breaking the bank. It’s perfect for hobbyists, tinkerers, and anyone who wants to dip their toes into the 3D printing world without diving headfirst into the deep end of their wallet. And let’s not forget, with a little TLC, FDM can produce some seriously impressive detailed prints.

SLA: The Detail Diva

SLA is for those who demand perfection in their prints. It’s the go-to for jewelry makers, dentists, and anyone else who needs small, highly detailed objects. If you’ve ever wanted to 3D print the world’s tiniest violin to play when someone complains about their first-world problems, SLA is your jam.

SLS: The Industrial Powerhouse

SLS is the heavyweight champion of the 3D printing world. It’s not here to play games; it’s here to produce tough, functional parts that can withstand real-world use. If you need to print a replacement part for your rocket ship (you have one of those, right?), SLS has got you covered.

Resin: The Jack of All Trades

Resin printing sits in a sweet spot between SLA’s detail and FDM’s ease of use. It’s perfect for those who want high-quality prints without the complexity of SLA or the industrial-scale of SLS. Plus, it makes your workspace smell like a science experiment, which is a bonus if you’re into that sort of thing.

Wrapping It Up: The Blind Guy’s Perspective

As a blind guy fumbling his way through the 3D printing world, I’ve learned that each of these technologies has its place. It’s like trying to decide between a fork, a spoon, a knife, or chopsticks. They’re all great, but you wouldn’t want to eat soup with a fork or steak with a spoon (though I’d pay good money to watch someone try).

FDM is my go-to for most projects. It’s simple enough that even I can’t mess it up too badly, and the results are tangible enough for me to appreciate. With some fine-tuning, I can get pretty detailed prints that never fail to impress (even if I have to take everyone else’s word for it). SLA and resin printing, while amazing, require a level of visual inspection that’s a bit challenging for someone who can’t see the difference between a perfect print and a blob that vaguely resembles a mutant potato.

SLS, well, that’s still in the realm of my dreams. But hey, a blind guy can dream, can’t he?

In the end, the best 3D printing technology is the one that works for you. Whether you’re printing miniatures for your D&D campaign, prototyping the next big invention, or just making really complicated paperweights, there’s a 3D printing technology out there for you.

So go forth, my fellow makers and tinkerers! Experiment, create, and don’t be afraid to make a mess. After all, that’s half the fun of 3D printing. Just maybe wear gloves. And a mask. And goggles. You know what? Just wear a hazmat suit. Safety first!

Until next time, this is your blind 3D printing enthusiast, signing off. Remember, in the world of 3D printing, we’re all feeling our way through the dark. Some of us just have more practice at it than others!